The Duty of Modern Technology in Modern Welding Inspection Madison Practices

The Duty of Modern Technology in Modern Welding Inspection Madison Practices

Blog Article

Discovering Advanced Tools and Approaches for Accurate Welding Assessment

In the realm of welding inspection, the search of accuracy and integrity is critical, stimulating the development of sophisticated devices and approaches. Technologies such as phased array ultrasonic screening and electronic radiography are changing issue discovery, providing unequaled precision in defining welding flaws. Furthermore, laser scanning developments and computerized examination systems, equipped with expert system, are redefining the landscape by lowering human mistake and improving precaution. As these sophisticated methods continue to evolve, they promise not only to transform evaluation methods yet likewise to elevate fascinating concerns about the future of quality control in industrial applications.

Ultrasonic Testing Technologies

Ultrasonic testing technologies frequently stand for the leading edge of developments in welding examination innovations. These developments have actually dramatically boosted the capability to detect and examine gaps within bonded structures, ensuring enhanced stability and safety and security - Welding Inspection Madison. Ultrasonic screening employs high-frequency acoustic waves to penetrate materials, supplying thorough details about interior functions without creating damage. The most recent growths in this field have actually concentrated on enhancing precision, speed, and the capability to interpret complicated information.

In addition, developments in software program algorithms for information analysis have actually improved the precision of issue detection and sizing. Automated ultrasonic testing systems currently offer high-resolution imaging, making it possible for in-depth evaluations of weld quality. These systems are usually incorporated with advanced visualization devices, which assist in the analysis of results.

Radiographic Examination Techniques

While ultrasonic screening developments have set a high criterion in non-destructive examination, radiographic evaluation methods remain to play an integral role in welding assessment by supplying special understandings into product integrity. Radiographic screening (RT) utilizes the usage of X-rays or gamma rays to permeate materials, developing a radiograph that visually stands for the internal framework of a weld. This imaging ability is invaluable for finding subsurface defects such as porosity, additions, and fractures that might not be noticeable with surface area examinations.

The procedure entails positioning a radiation resource on one side of the weld and a detector on the contrary side. Variants in material thickness and thickness influence the depletion of the rays, creating a contrasting picture that exactly delineates defects. RT is particularly beneficial for inspecting complicated geometries and thick areas where various other techniques may fail.

Regardless of its efficiency, radiographic inspection has to be performed with rigorous adherence to safety and security procedures as a result of the unsafe nature of ionizing radiation. Moreover, the analysis of radiographs requires knowledgeable personnel, as the top quality of the evaluation directly impacts the integrity of the assessment. Ongoing improvements in digital radiography are boosting picture quality and interpretation performance, strengthening RT's critical function in ensuring weld high quality.

Laser Scanning Breakthroughs

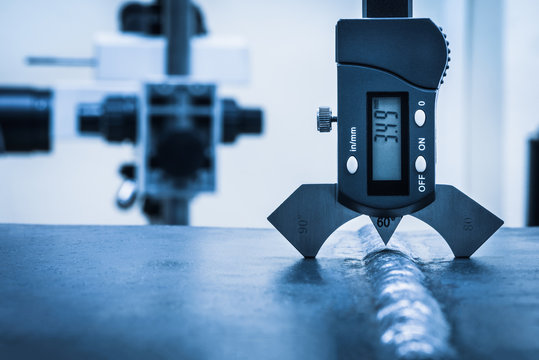

Accepting laser scanning innovation in welding examination has actually revolutionized the assessment of weld quality and stability. Unlike typical inspection techniques, laser scanning offers fast data acquisition, considerably improving the effectiveness and accuracy of weld assessments.

Laser scanning developments have actually caused considerable enhancements in finding and identifying surface flaws such as porosity, lack of fusion, and undercuts. The high-resolution data enables inspectors to carry out detailed evaluations, making sure that welds satisfy stringent sector requirements. Moreover, this technique supports the growth of digital documents, promoting long-lasting quality control and traceability.

Furthermore, laser scanning innovation integrates perfectly with software solutions designed for automated defect detection and evaluation. The resultant data can be easily shared and examined, advertising joint decision-making procedures. As sectors remain to require greater standards for weld high quality, laser scanning remains at the forefront, providing exceptional accuracy and effectiveness in welding inspection.

Automated Evaluation Equipments

Automated assessment systems offer the advantage of consistency, getting rid of human mistake and subjectivity from the inspection procedure. They are designed to run in numerous settings, from manufacturing floors to remote area sites, making certain comprehensive coverage. Welding Inspection Madison. These systems can be programmed to adhere to details welding requirements and standards, providing detailed records and paperwork for quality assurance functions

In addition, the integration of cloud-based platforms promotes the storage and evaluation of substantial amounts of inspection information. This makes it possible for pattern evaluation and anticipating upkeep, enabling makers to address potential issues before they rise. The fostering of automatic examination systems is a crucial action in the direction of boosting the Full Report integrity and performance of welding processes in industrial applications.

Enhancing Security and Efficiency

A considerable aspect of enhancing safety and security and efficiency in internet welding inspection depends on the combination of cutting-edge innovations that improve procedures and mitigate dangers. The adoption of sophisticated non-destructive testing (NDT) techniques, such as ultrasonic screening, phased selection ultrasonic screening (PAUT), and radiographic testing, plays a crucial duty in guaranteeing structural stability without compromising the safety of the personnel involved. These methods enable for thorough assessments with minimal downtime, decreasing potential threats related to conventional approaches.

Moreover, the application of real-time data analytics and machine understanding algorithms has changed the way inspection data is interpreted. By utilizing predictive analytics, possible issues can be identified prior to they manifest into essential failures, guaranteeing prompt treatments and upkeep. This aggressive method significantly improves functional efficiency and safety in welding processes.

In addition, remote examination technologies, including drones and robotic crawlers equipped with high-resolution cameras, enable inspectors to analyze hard-to-reach locations without revealing them to hazardous conditions. This not only improves examination accuracy yet also lessens human threat. By leveraging these sophisticated tools and approaches, markets can accomplish higher safety criteria and functional efficiency, ultimately causing more sustainable and trusted welding assessment techniques.

Conclusion

The combination of innovative tools and methods in welding inspection considerably improves issue detection and makes certain architectural integrity. These advancements not only increase inspection performance yet additionally contribute to boosted safety and security and high quality guarantee in industrial welding applications.

Ultrasonic testing technologies regularly stand for click to find out more the forefront of improvements in welding evaluation modern technologies.While ultrasonic testing advancements have actually set a high requirement in non-destructive exam, radiographic examination methods continue to play an essential duty in welding inspection by using unique understandings into product honesty.Embracing laser scanning modern technology in welding evaluation has actually changed the assessment of weld high quality and integrity. As industries continue to require greater standards for weld high quality, laser scanning continues to be at the forefront, providing exceptional accuracy and performance in welding evaluation.

Automated evaluation systems use the advantage of consistency, eliminating human error and subjectivity from the evaluation procedure.

Report this page